Our Core Values – Geethanjali Engineering Industries

Precision Engineering

Every component we manufacture or service we deliver meets the highest industry standards.

Continuous Improvement

We invest in new technologies and training to enhance our processes.

Custom Solutions

We don’t just follow trends—we engineer tailored fixes for unique challenges.

Timely Delivery

We respect deadlines because your time is valuable.

About us

Precision Engineering Solutions for Cement, Sponge iron & Chemical Industries

Welcome to Geethanjali Engineering Industries (GE), a leading provider of heavy engineering solutions since 2007. We specialize in design, manufacturing, installation, and maintenance of industrial equipment for cement plants, Sponge Iron, and chemical industries. With a strong commitment to quality, innovation, and timely execution, we serve top-tier clients like Jindal Group, Sagar Cement, Monnet Groups, and Rayalaseema Sugar & Chemicals.

Advanced Machinery & Skilled Workforce

Our Clients

Our Services

Comprehensive Engineering Services for Industrial Excellence

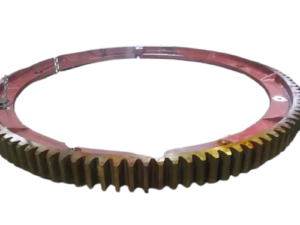

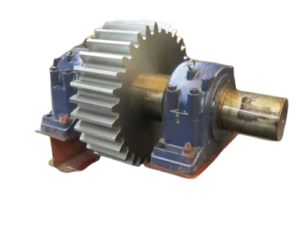

Our Product Range

At Geethanjali Engineering Industries (GE), we manufacture and supply high-performance industrial equipment and components for cement plants, chemical industries, power sectors, and steel manufacturing units. Our products are built with precision engineering, superior materials, and rigorous quality checks to ensure durability and efficiency in demanding industrial environments.

why choose us

Proven Expertise | End-to-End Solutions | Unmatched Reliability

✅ 15+ Years in Heavy Engineering

✅ End-to-End Project Execution

✅ Quality Fabrication & Machining

✅ 24/7 Maintenance Support

✅ Trusted by 50+ Industrial Clients

Industries We Serve

- Cement

- Sponge Iron

- Chemicals

- Sugar & Fertilizers

Work Process

Make It Happens In 4 Steps

Video Introduction

Requirement Analysis

Design & Engineering

Manufacturing & Testing

Installation & Support

Our Manufacturing Capabilities

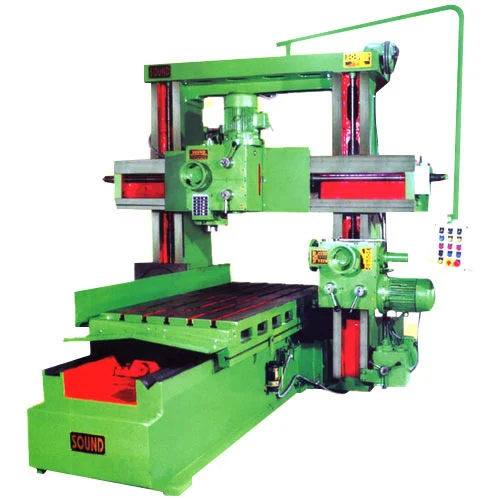

Machining Facilities

Heavy Lathe (Up to 15ft diameter capacity)

Plano Milling (6m x 2m table)

Gear Cutting (Up to 5m diameter)

Radial Drilling (100mm capacity)

CNC Plasma Cutting (50mm thickness)

H-Boring Machine

Plano Milling Machine

Radial Drilling Machine.

15ft Lathe,

Plasma Cutting Machine (up to 50mm).

Vertical Lathe Machine

Our Gallery